Helpful Articles

Hydraulic Lifts 0

Introduction

Here is everything you want to know about hydraulic lifts.

You will learn:

- What is a Hydraulic Lift?

- How do Hydraulic Lifts Work?

- Types of Hydraulic Lifts

- Hydraulic Lift Tables

- And much more…

Chapter One – What is a Hydraulic Lift?

A hydraulic lift is a device for moving objects using force created by pressure on a liquid inside a cylinder that moves a piston upward. Incompressible oil is pumped into the cylinder, which forces the piston upward. When a valve opens to release the oil, the piston lowers by gravitational force.

The principle for hydraulic lifts is based on Pascal‘s law for generating force or motion, which states that pressure change on an incompressible liquid in a confined space is passed equally throughout the liquid in all directions.

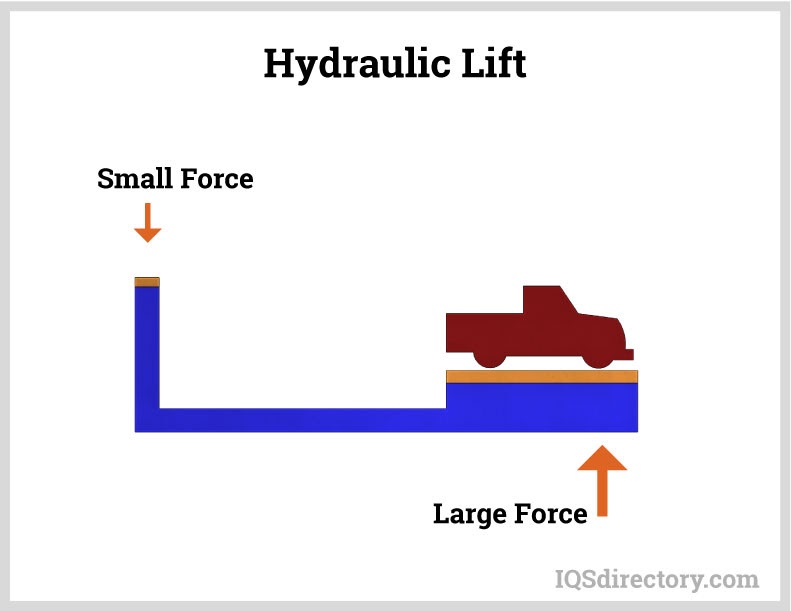

The concept of Pascal‘s law and its application to hydraulics can be seen in the example below, where a small amount of force is applied to an incompressible liquid on the left to create a large amount of force on the right.

Hydraulic systems are used for precision control of large force applications, are economical, and make excellent use of energy resources.

Chapter Two – How do Hydraulic Lifts Work?

A hydraulic system works by applying force at one point to an incompressible liquid, which sends force to a second point. The process involves two pistons that are connected by an oil filled pipe.

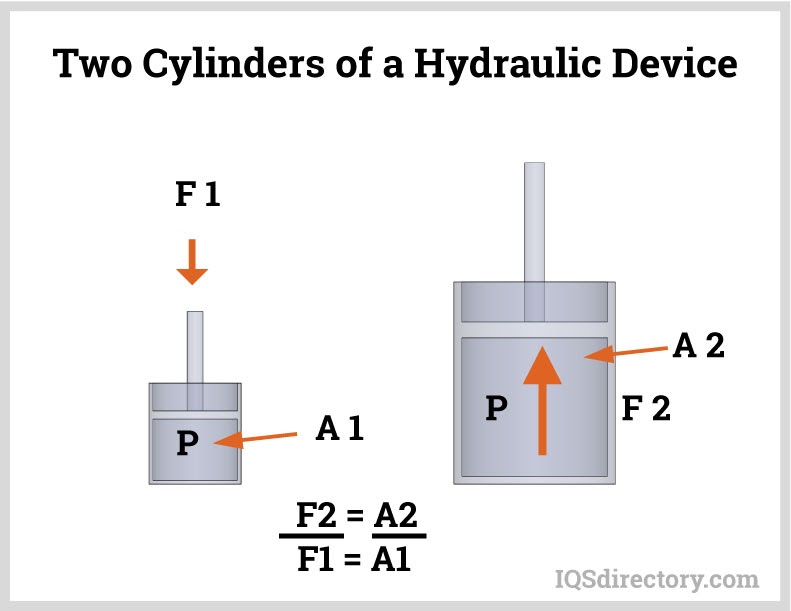

The image below is a representation of the two pistons and how they are connected by a pipe.

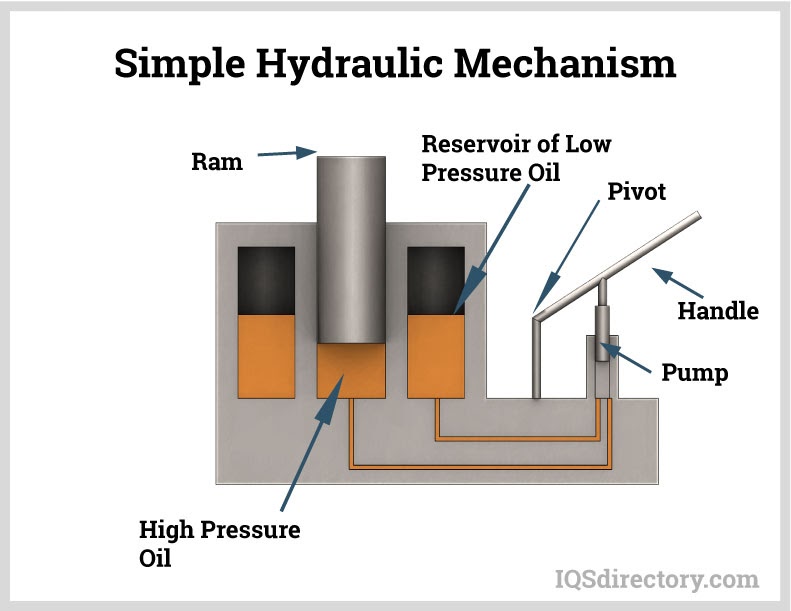

The diagram below represents a simple version of the working mechanism of a hydraulic device. The handle on the right moves the incompressible oil, under pressure, from the reservoir to the high pressure chamber in the middle of the diagram. The ram moves up as the oil is pumped in.

Force Generated

The force generated in a hydraulic system depends on the size of the pistons. If the smaller of the two pistons is two inches and the larger piston is six inches, or three times as large, the amount of force created will be nine times greater than the amount of force from the smaller piston. One hundred pounds of force by a small piston will be able to lift 900 pounds.

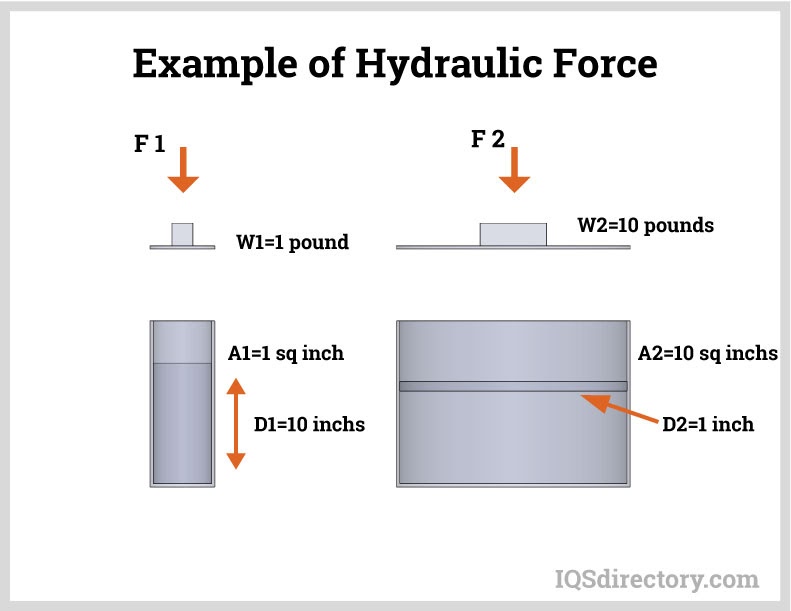

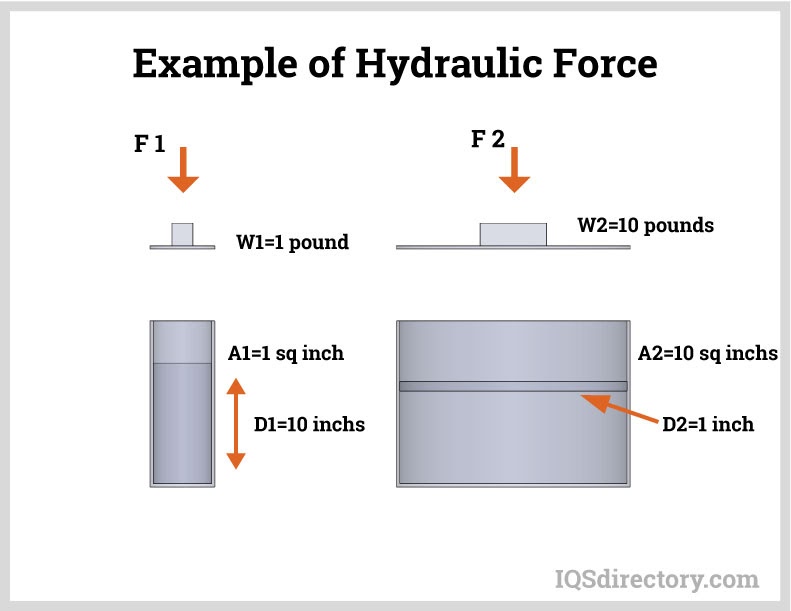

In this diagram, the piston on the left has a one pound load and an area of one inch. When it moves down ten inches, it is able to move the ten pound load on the piston on the right.

Parts of a Hydraulic System

The purposes of hydraulic systems widely vary, but the principles of how hydraulic systems work and their components remain the same for all applications. The most significant part of a hydraulic system is the fluid or liquid. The laws of physics dictate that the pressure on the fluid will remain unchanged as it is transmitted across a hydraulic system. Below is an explanation of each part of a hydraulic system.

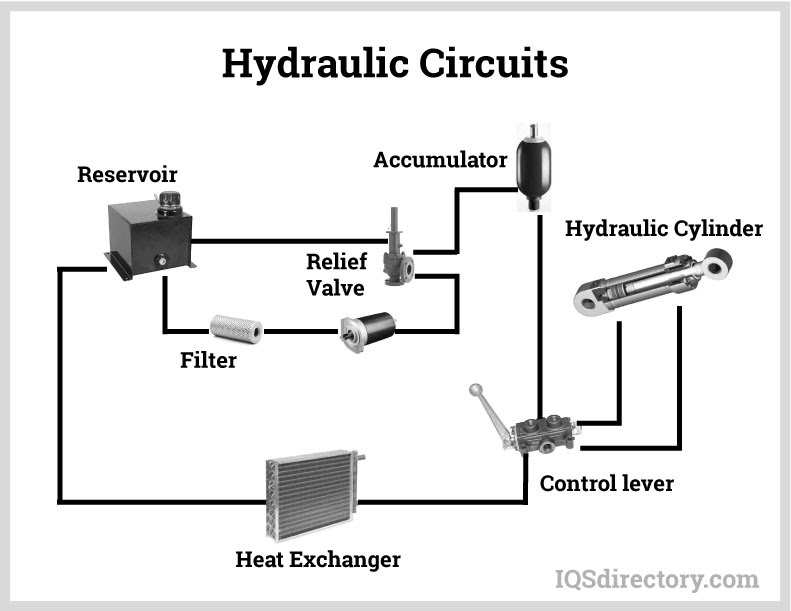

Hydraulic Circuits:

Hydraulic Circuits control the flow and pressure of the liquid in the system. The image below shows all of the different parts of a hydraulic circuit.

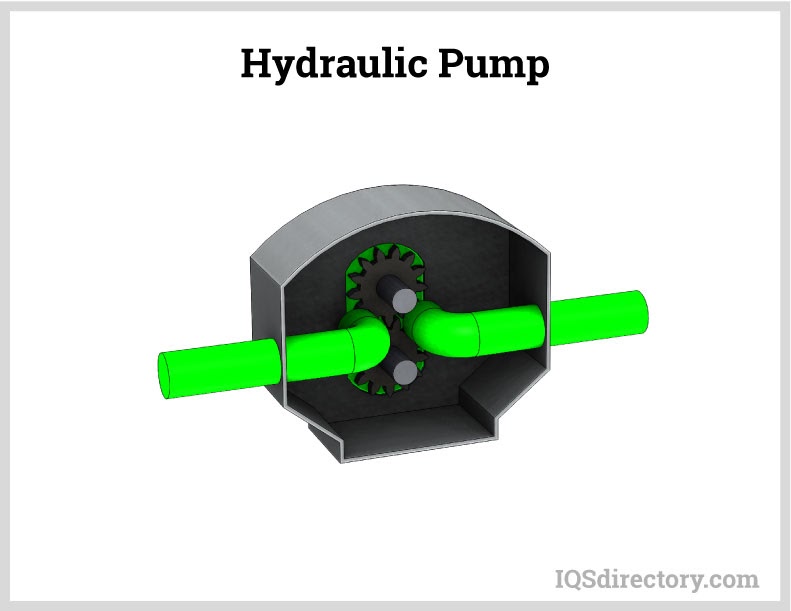

Hydraulic Pump:

Hydraulic Pump converts mechanical power into hydraulic energy. Hydraulic pumps create a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line and out to the outlet to the hydraulic system.

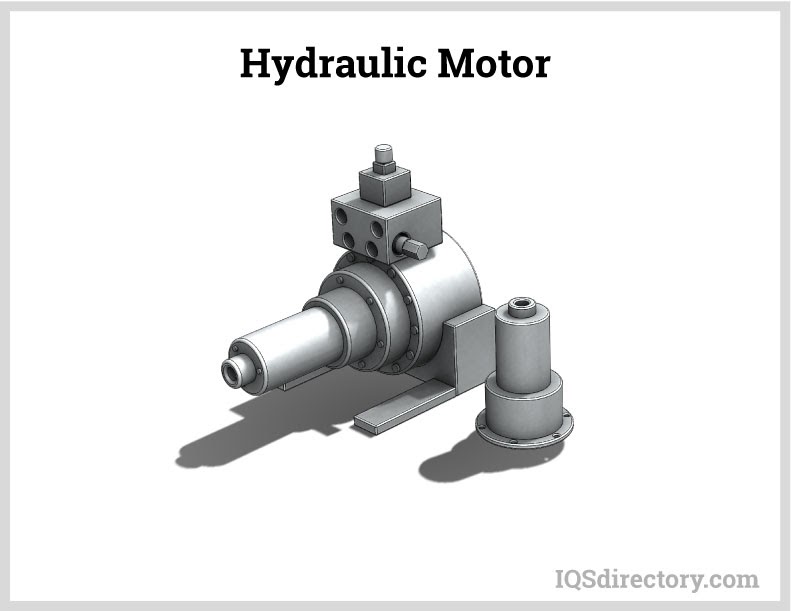

Hydraulic Motor:

Hydraulic Motor is an actuator to convert hydraulic pressure into torque and rotation. It takes the pressure and flow of the hydraulic energy and changes it into rotational mechanical energy, similar to a linear actuator. The pump sends hydraulic energy into the system, where it pushes the hydraulic motor.

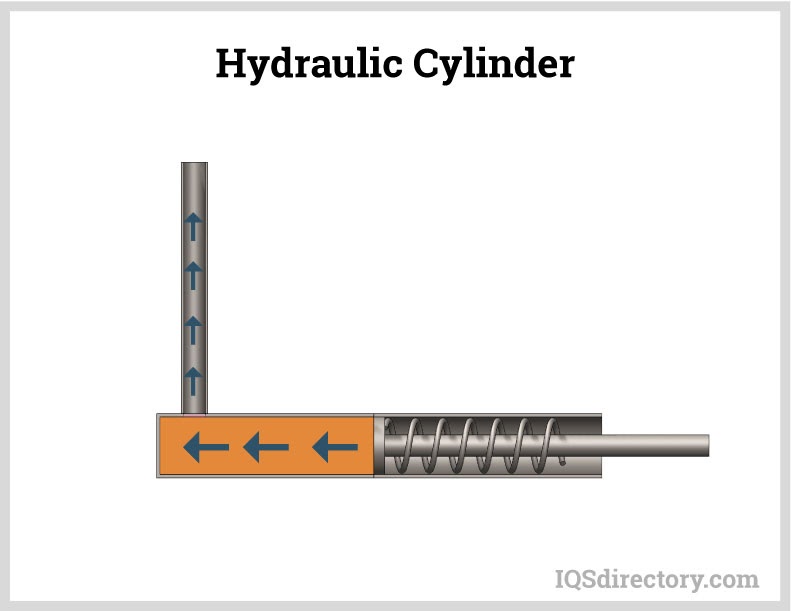

Hydraulic Cylinder:

Hydraulic Cylinder converts the energy in the hydraulic fluid into force and initiates the pressure in the fluid that is controlled by the hydraulic motor.

Hydraulic Pistons:

Hydraulic Pistons are moved linearly by fluid pressure. Axial designs have a number of pistons arranged in a circular pattern in a rotating housing.

Hydraulic Fluids:

Hydraulic Fluids transfer power in a hydraulic system. Most hydraulic fluids are mineral oil or water. The first hydraulic fluid was water before mineral oil was introduced in the twentieth century. Glycol ether, organophosphate ester, polyalphaolefin, propylene glycol, and silicone oil are used for high temperature applications and fire resistance.

Leading Hydraulic Lift Manufacturers and Companies

Chapter Three – Types of Hydraulic Lifts

Hydraulic lifts, in their many forms, have become an essential part of several industries from helping patients in and out of bed to specially designed lifts to help people board a bus. The number of uses of hydraulic lifts has been growing rapidly in recent years.

Below are descriptions of a few types of hydraulic lifts.

Table lifts:

Table lifts are used to move items from the floor to a workable level. Transportation companies use them to lift materials onto a truck bed or warehouse floor.

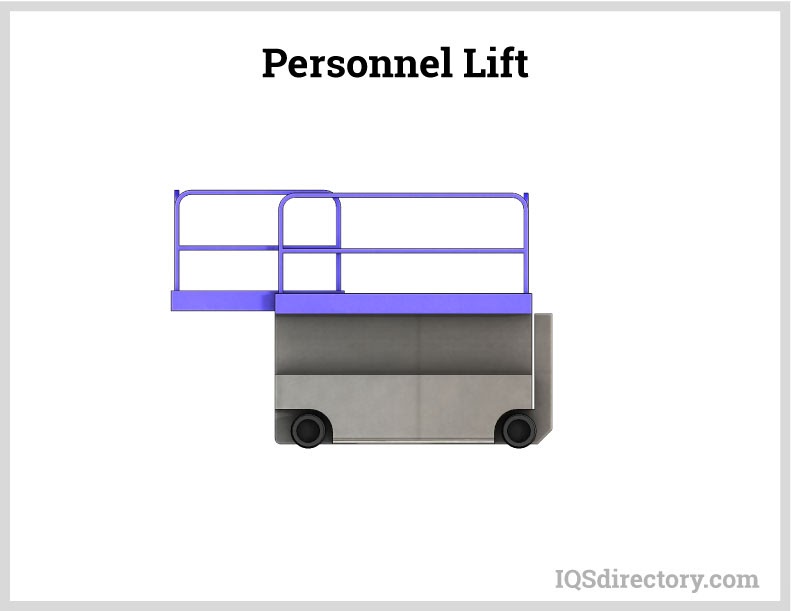

Personnel lifts:

Personnel lifts safely lift people to various heights for work or movement of materials, such as repair of electrical lines, placement of inventory on a shelf, or access to control boxes. In gyms, factories, and entertainment centers, they are used to lift janitorial staff to clean lights and ceilings.

Fork lifts:

Fork lifts are used for moving materials at construction sites, in warehouses, in factories, and for loading and unloading trucks and airplanes. They are designed to quickly move items from one location to another.

Medical lifts:

Medical lifts are lifting devices for surgical tables, hospital beds, and monitoring equipment. Hospital beds are a convenient means for moving patients from their rooms to treatment areas. Hydraulics control the height of all parts of the bed to make it more acceptable for hospital staff.

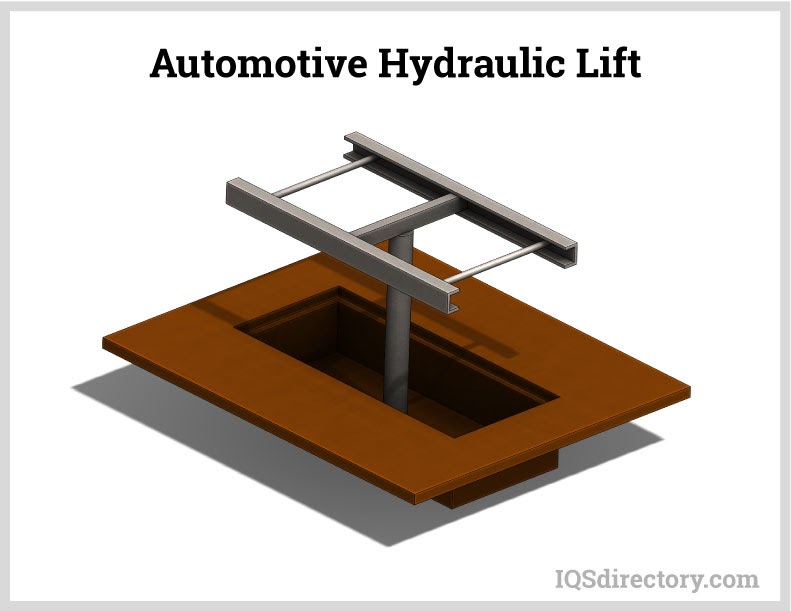

Automotive lifts:

Automotive lifts lift vehicles for repair and inspection. They are the strongest of the different types of hydraulic lifts.

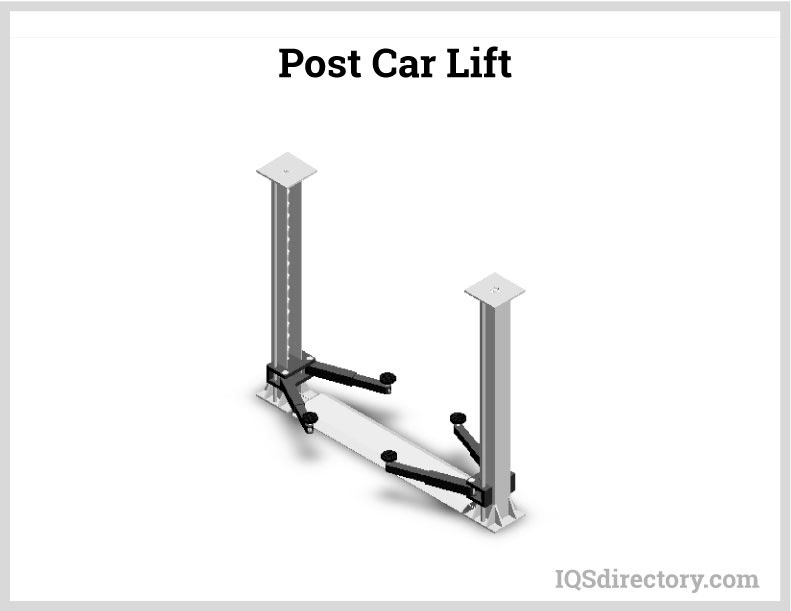

Post car lifts:

Post car lifts are a variation of automotive lifts. The vehicle to be repaired is suspended between two posts with hydraulic drives that have four arms. They are designed to lift any type of vehicle.

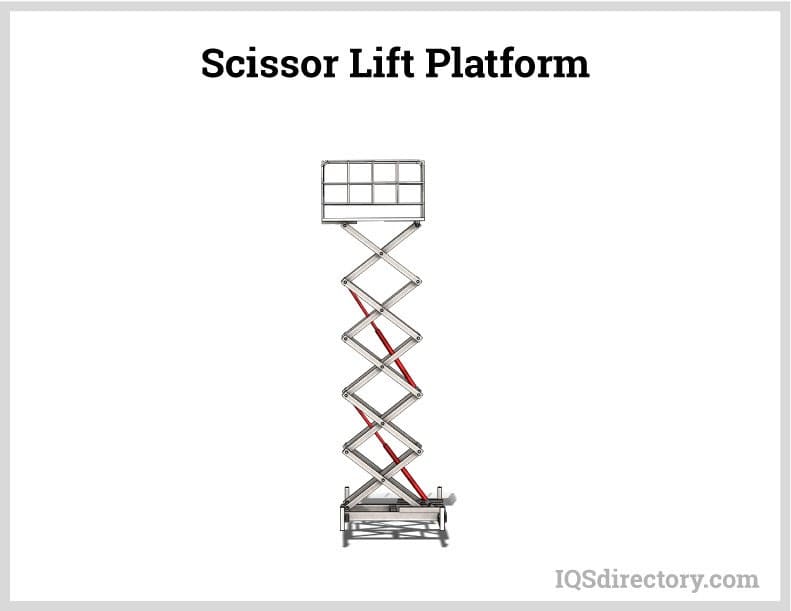

Platform lifts:

Platform lifts also known as elevated work platforms, are similar to lift tables but much larger. They are able to hold groups of workers.

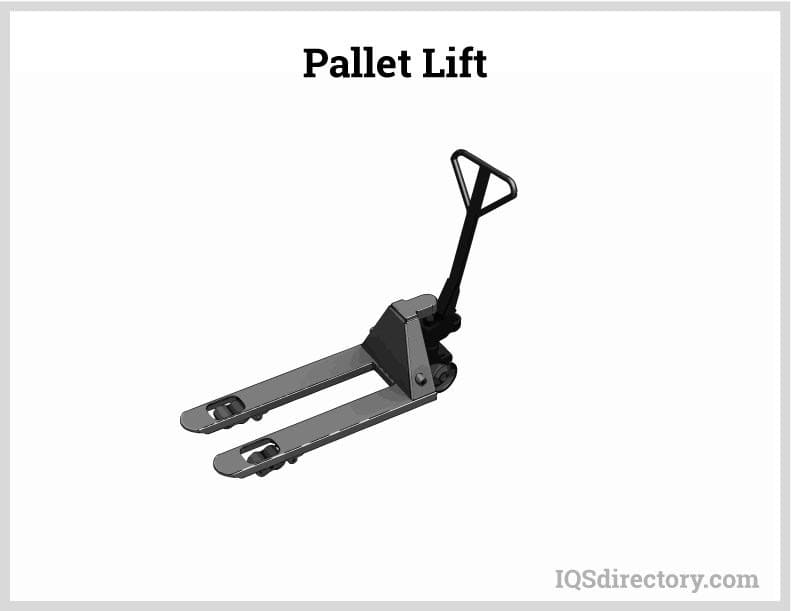

Pallet lifts:

Pallet lifts are used for material handling and shipping. They function like a forklift and are able to lift pallets from ground level to load trucks, place on shelves, or move supplies to production lines.

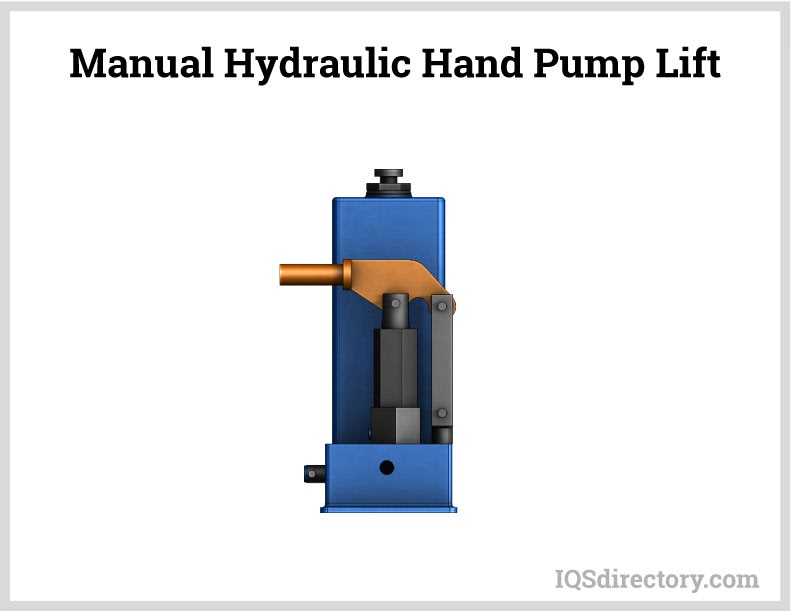

Hand pumped lifts:

Hand pumped lifts are raised by a manual hydraulic hand pump and have a release lever to lower the load. They are very sturdy and maintenance free with the ability to lift one ton over six feet.

Vertical Reciprocating Conveyor (VRC)

VRCs, also known as vertical, vertical material, freight, and conveyor lifts, are classified by the American Society of Mechanical Engineers (ASME) as conveyors and related equipment. They can be placed anywhere in a building and are designed to move large loads from the floor to mezzanines, balconies, basements, and various levels in a multiple level building.

Unlike the installation of an elevator, a VRC can be easily positioned at far less cost but provide the same type of lifting power. If there isn‘t sufficient room on the interior of a building, a VRC can be positioned outside.

The main components of a VRC are a guide column, carriage, and hydraulic actuating mechanism or mechanical system. VRCs can be mechanical or hydraulic with the hydraulic version being less expensive than mechanical ones. Hydraulic VRCs can lift loads of a half-ton up to three tons with a carriage size of 10 feet by 10 feet and can reach heights over 20 feet with ease.

Types of VRCs

- Straddle – The carriage is between guide beams. Force is applied in a vertical direction along the length of the beams.

- Cantilever – The carriage is out in front of the guide beams and can be accessed from three sides.

- Four Post – The platform is positioned in the middle of four guide beams and may have a larger platform capable of lifting heavier loads.

- Double Mast – The double mast version is similar to the four post design with the carriage positioned between two sets of masts. It has a smaller platform and lifting capacity than the four post design.

Chapter Four – Hydraulic Lift Tables

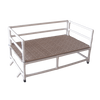

Lift tables have become popular as work surfaces that can be positioned at the exact height necessary to package, assemble, organize, or position items. What makes lift tables different from adjustable tables is their capacity.

A standard lift table is able to lift 2000 to 6000 lbs. and can be lowered to 7 inches or raised to 60 inches with a work space of 24 to 72 inches. They come in a variety of shapes and sizes to fit any application. Below is a description of some of the varieties of lift tables.

Mobile

Mobile lift tables, or lift carts, are a form of push cart. They are raised by a manual foot pump for light assembly operations.

Rotating

Rotating lift tables are used where access to all sides of the load is required. They are designed with a rotating platform and can have reduced heights, which allows for greater access.

Low profile

Lower profile lift tables are designed to reach heights as low as 3 inches making the platform accessible by a pallet jack. Though they have thinner lifting arms, they still have a capacity of over 2200 lbs.

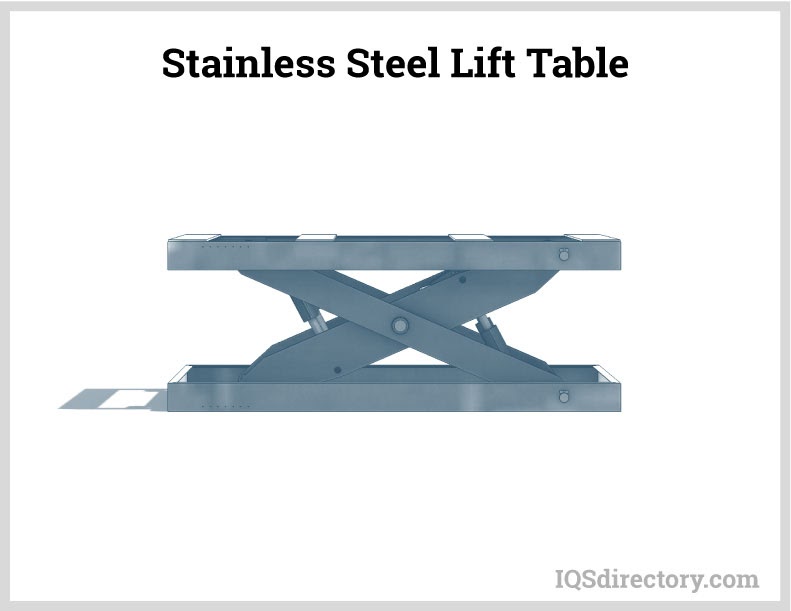

Stainless steel

Stainless steel lift tables are mainly used in the food and pharmaceutical industries, where there are high standards for hygiene and sanitary conditions. The corrosion and rust resistance of stainless steel makes them easy to clean with solvents and water.

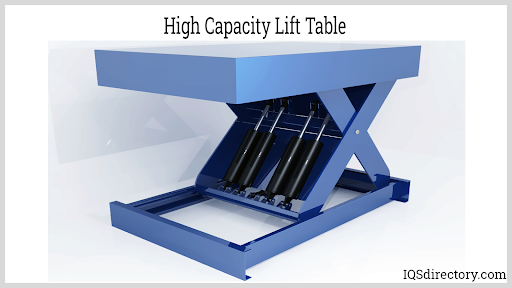

High capacity

High capacity lift tables can have a capacity of 8,000 to 10,000 lbs. As seen in the image below, they have extra thick scissor arms, large low pressure cylinders, and additional supports.

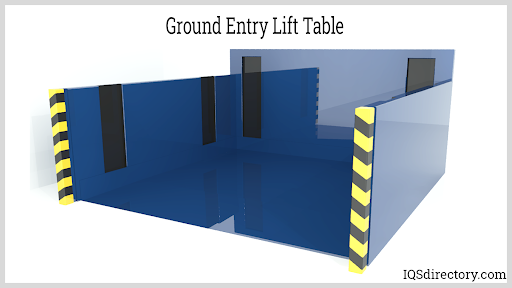

Ground entry

Ground entry lift tables have ground level access to the platform due to concerns regarding tripping or being in confined spaces. Access to the platform is by a cut away section in the shape of a "U" or "E", which makes them able to be loaded with an open bottom pallet or skid.

Tilting

Tilting lift tables are for handling containers with loose parts. The platform lifts to an ergonomic height and tilted toward the operator, which reduces the need for bending and stretching. They are available with tilt angles of up to 90 degrees.

Tandem

Tandem lift tables combine standard lifting with additional lifts of length or width providing the extra benefit of increased platform size to accommodate larger loads with extra edge and side load capacity.

Multi-Stage

Multi-stage lift tables stack one pair of scissor arms on top of another with one lift table on top of another, which increases vertical travel but maintains small platform size.

Chapter Five – Hydraulic Lift Applications

Hydraulic lifts are constructed from steel and have precision accuracy. Their sturdy and durable design has made them popular in a wide variety of industries. Listed below are a few of the industries that rely on hydraulic lifts for their efficiency and ability to supply a great amount of force.

Hydraulics Applications

Industrial:

Electro-hydraulics is a common use of hydraulics in industrial applications. The main advantages of hydraulics are its rapid response times and precision. Plastic processing, metal extraction applications, automated production, machine tool industry, paper industries, loaders, crushers, presses, and the textile industry are some of the industrial uses of hydraulics. The image below is a hydraulic press from the plastics industry.

Mobile Hydraulics:

Mobile hydraulics have the advantage of being able to be moved to different conditions and situations. They are especially useful in the construction and building industries where hydraulics are used as cranes, excavators, backhoes, and earth moving equipment. Pictured below is a concrete boom truck using a hydraulic arm to unload concrete.

Automobiles:

The automotive industry is the largest user of hydraulics. Production, repair, and internal components on cars all use hydraulics.The image below shows the use of hydraulic automation in the production of trucks.

Marine Applications:

Marine hydraulics deliver linear and rotary force and torque rapidly and efficiently. The three types of marine hydraulic systems are open, closed, and semi-closed. They are used for cranes, mooring and anchor winches, stabilizers, steering, thrusters, propellers, and platforms.

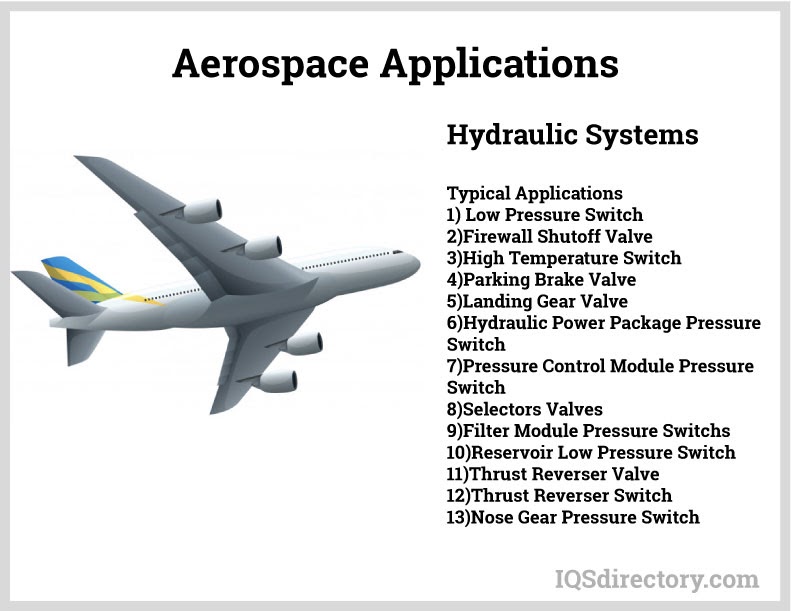

Aerospace Applications:

Components for aircraft have to meet strict standards before being approved for use. Hydraulic pumps and valves meet aircraft regulations and are an essential part of aircraft design and production. Wing adjustments, retraction and extension of landing gear, opening/closing of doors, brakes, and steering are all performed by hydraulics. The image below provides a list of some of the ways hydraulics are used on an aircraft.

Mining:

Hydraulics are ideal for mining for the same reasons that they are used for other manufacturing operations. Power, controllability, reliability, and serviceability are necessities in mining because of the dangers that are involved. Unlike other manufacturing, mining works on a huge scale requiring massive equipment. The power and force provided by hydraulics fits the conditions.

Chapter Six – Safety Regulations for Hydraulic Lifts

Hydraulics lifts are heavy duty equipment that can supply a great deal of force. The Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) have specific requirements regarding the operation of hydraulic lifts. The first of those requirements is that operators must be an adult, over 18, that has been fully trained in the operation and dangers of the equipment.

Below is a summary of regulations and safety tips regarding hydraulic lifts.

OSHA Regulations:

OSHA regulations regarding lifts are generalized to include any form of work that has to be performed on a platform off the ground.

Standard 1926.451 – Safety and Health Regulations for Construction – Though this seems to be directed at construction, it covers the requirements for guardrails and fall protection. The general outline is for scaffolds but has been expanded to apply to lifts.

Standard 1910.29 – Walking-Working Surfaces – This covers fall protection systems and protection from falling objects. It further covers guardrails and railings.

ANSI A92

Aerial lifts are defined as mobile elevating work platforms (MEWPs). ANSI A92 requires aerial lifts to be equipped with two types of sensors: one that sounds an alarm and prevents the machine from operating when the load exceeds safety limits, and another that triggers an alarm when the slope level gets too steep and prevents movement of the chassis or work platform.

Gates cannot be chains and must have toe guards. If used for outdoor work, wind speed sensors are required. Platform railings must be at 43.5 in. or greater. If used on uneven ground, tires must be solid or foam filled. Also included in A92 are expanded training requirements.

Aerial Lift Certification:

To be OSHA certified to operate aerial and scissor lift equipment, an operator has to pass an OSHA certified course, which is designed to aid workers on how to safely operate lift equipment. The regulations and stipulations for operating lift equipment legally require employers to provide certification training.

Training includes:

- OSHA Standards for Aerial and Scissor Lifts

- Definitions of Lift Related Terms

- Aerial & Scissor Lifts Accidents, Fatalities, and Causes

- Fall Protection

- Operating Instructions

- OSHA Safe Work Practices

- Scissor Lifts Operator Training

- Lift Operator Responsibilities

Safety Tips:

- Understand and follow the manufacturer‘s instructions.

- The lift should be marked with the name of the manufacturer and date of installation.

- A repair log must be maintained.

- Workers should stand to one side as the lift operates.

- The load should rest squarely on the lift and not overload the lift‘s capacity.

- Lifts must be kept away from overhead and grade level obstacles.

- The floor under the lift should be free of oil or grease to prevent slipping hazards.

- Avoid holes, trenches, slopes, or uneven terrain.

- The lift must be at least10 feet away from electrical lines and power sources.

- Oil levels on hydraulic lifts should be checked periodically.

- Lifts should be removed from service if there are any indications of malfunctioning.

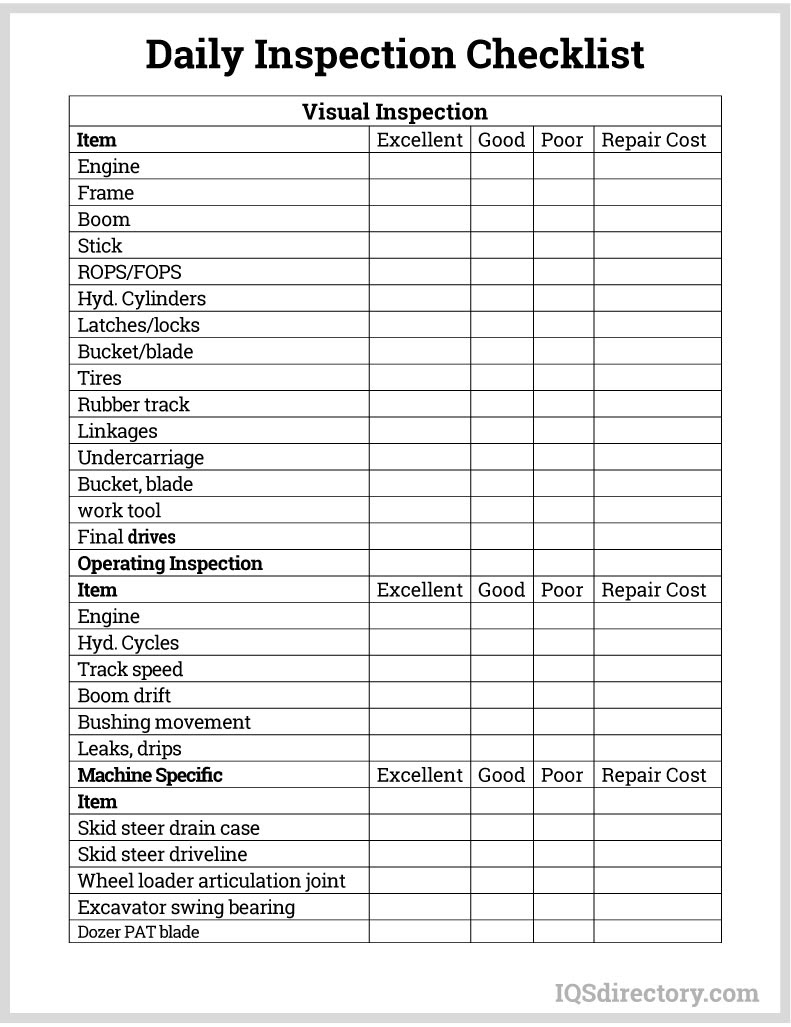

Below is a sample daily checklist for hydraulic lifts.

Conclusion

- A hydraulic lift moves objects using the force created by pressure on a liquid inside a cylinder that moves a piston upward.

- The principle for hydraulic lifts is based on Pascal‘s law for generating force or motion, which states that pressure change on an incompressible liquid in a confined space is passed equally throughout the liquid in all directions.

- Hydraulic lifts provide controlled and precision force.

- The sturdy and durable design of hydraulic lifts has made them popular in a wide variety of industries.

- The Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) have specific requirements regarding the operation of hydraulic lifts and training for operators.

- Lift tables have become popular as work surfaces that can be positioned at the exact height necessary to package, assemble, organize, or position items.

To learn more and view the original article, you may visit: Hydraulic Lifts | IQS Directory

Author: John Hamlin

John Hamlin is a freelance writer who has a background in engineering. With a keen interest in technology and writing, John has been working online providing insight and direction for many years. His latest work has been on a compilation of industrial manufacturing techniques.

- Dansons Medical

Knowing the Signs: Seniors and Assisted Living 0

Millions of Americans live alone in the United States today. While a good portion of these people are healthy, independent, and able to handle the demands of running a home, many others are not. If you are a caregiver for someone in this latter category, you may be wondering if living at home is still the best option. But how, exactly, do you know if it’s time to initiate a conversation about assisted living?

Visit Dansons Medical for high-quality medical and accessibility equipment.

Care Options

It is important to first know that assisted living is not necessarily your only option. Independent living may be a more palatable experience for seniors with a need for autonomy. According to Modern Retirement, independent living provides basic services, such as housing, housekeeping, and meal preparation. This type of assistance can help overall healthy and active seniors remain that way for years to come. Assisted living is similar; however, seniors in this type of community also have access to more hands-on care, such as assistance bathing, medication management, and managing most daily tasks. In many cases, you can find a continuing care community that will allow the senior to seamlessly transition from independent to assisted living.

Look Out For Warning Signs

It’s an unfortunate reality, but some seniors are embarrassed or even in denial about their inability to live alone. They may be remiss to answer questions about how they’re doing. As a caregiver, you’ll need to evaluate their situation without being overbearing. Look for warning signs, which include:

- Worsening health problems. This includes mobility issues, such as severe arthritis, emotional problems, like depression, and cognitive decline up to and including Alzheimer’s.

- Declining hygiene and cleanliness. All the above health problems might leave a senior unable to handle their hygiene or maintain the cleanliness of their home. While there’s nothing alarming about a coffee cup in the sink or using dry shampoo instead of taking a full shower every once in a while, body odor, outdated food in the refrigerator, and unmanaged pest problems are red flags.

- Worsening abilities on the road. The idea of losing driving privileges is terrifying to most older adults. But, as On Health asserts, some issues, such as mobility, vision, and hearing troubles, can all make it dangerous for a senior to get behind the wheel. If your loved one can no longer safely navigate the streets or public transportation, assisted living may be on the horizon.

Other potential problems to look out for include aggressiveness, neglected pets, isolation, and whether they have a network of friends and family that can step in when you are unavailable.

It’s Time to Talk

Only you know your loved one’s personality. Keep this in mind as you initiate the conversation. It’s almost always best to plant the proverbial seeds early, enlist the help of your siblings, aunts, uncles, and their same-age friends, and find out what they love so much about their home. When you finally bring up the possibility of assisted living, make sure they have nothing but a positive image, lots of support, and reassurance that they will get to bring the best of their current life with them.

It’s not going to be easy, but making sure a loved one is in the right situation for their mental, physical, and cognitive health is paramount to their quality of life. If you’re looking for further resources, the links below are great touch points that can help you get the process started when the time is right.

One Is the Loneliest Number: Combating Senior Isolation

Dementia Symptoms, Causes, Types, Stages, and Treatments

How to Make Seniors Feel at Home in a New Living Space

Forms Needed to Act on a Loved One’s Behalf

Author: Lydia Chan

Lydia is the co-creator of Alzheimer’s Caregiver, a website that aims to provide tips and resources to help caregivers. Her mom was diagnosed with Alzheimer’s and Lydia found herself struggling to balance the responsibilities of caregiving and her own life. She is passionate about sharing her knowledge and experiences with caregivers and seniors. In her spare time, Lydia finds joy in writing articles about a range of caregiving topics.

- Dansons Medical

6 Best Patient Lifts for Home Use 0

Patient lifts—medical devices for lifting and transferring patients from place to place—have enormous benefits for the well-being of both patients and caregivers.

For individuals with limited mobility, moving even short distances can be a major challenge. These movements pose injury risks for the person being moved as well as the person doing the lifting.

Fortunately, great progress has been made in developing lifts that safely meet the needs of patients and caregivers. Using a variety of technologies, configurations, and materials, there are some incredible lifts on the market today that are suitable for home use.

These devices improve mobility, reduce injury, and maximize the comfort and dignity of those that need them.

The Dansons Medical team is here to help you find solutions to your home health medical equipment challenges. We know how difficult it can be for both patient and caregiver to adjust to major changes in medical needs and physical abilities.

That’s why we’re here to help however we can. If you need a patient lift, we offer a premier selection along with the fastest and most reliable service that we can provide.

In this guide, we’ll review the two primary categories of lifts: electric and hydraulic lifts.

Looking for a lift for home use? We’ll highlight a few of the best offerings from each category, but be sure to view our entire patient lift inventory before making your choice.

Electric Patient Lifts

An electric patient lift works via battery power. The operator can simply press a button to mobilize the device. That means relief from heavy exertion and pain while maneuvering a patient transfer.

Battery power also eliminates the presence of a power cord during the use of the device. No power cord in the way means that it’s easier to complete a lifting movement without tripping or needing to stop to move the cord.

Here are a few top-of-the-line electric patient lifts:

BestLift PL350CT

The BestLift PL350CT was designed as an electric lift with a battery option. It’s portable and foldable, making it extremely transportable. The key features are as follows:

- 350lb Capacity

- Convertible/Portable

- Electric System

- Compatible with most plastic clip slings

Its unique spreader bar is the reason why it's one of the only patient lifts in the market right now with a spreader bar specifically designed for easy patient handling from a car.

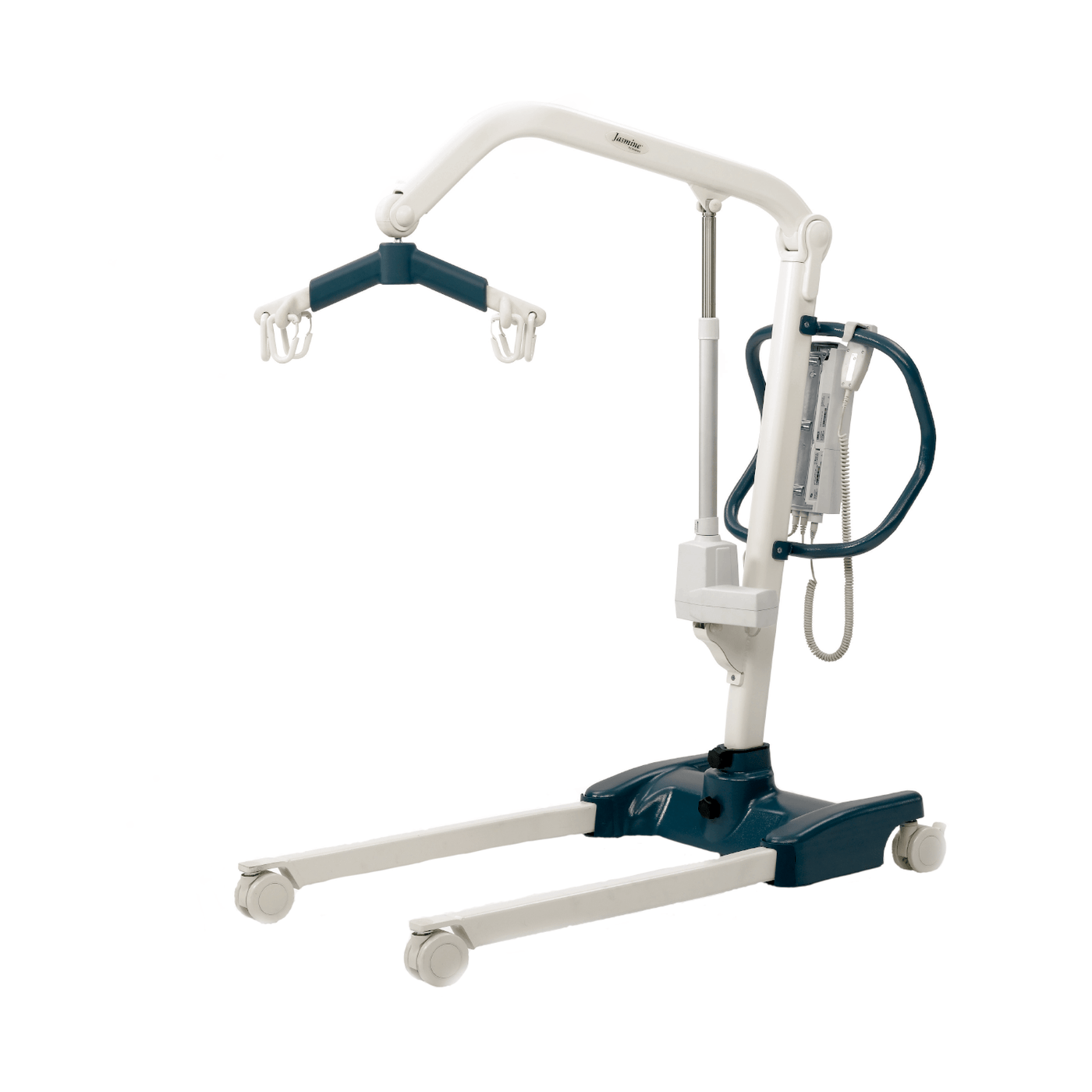

Invacare Jasmine Full Body Lift

Invacare JASMINE Full Body Lift

The Invacare Jasmine Full Body Lift is made from lighter-weight aluminum and steel, allowing for easier transportation. The key features are as follows:

- Battery-powered

- 500lb capacity

- 6-point hanging bar

- Powered boom and base controlled by hand pendant

The Jasmine includes a rotating 6-point hanger bar for assisting patients that have fallen. The base presents a wide opening so that caregivers can comfortably walk behind the patient while a wheelchair can be accommodated up front.

Hoyer Presence Professional Patient Lif

Hoyer Presence Professional Patient Lift

The Presence’s Smart Monitor technology displays lifting activity to help drive user compliance. The Presence can lift patients from the floor, accommodate transfers to higher surfaces, and manage a 500lb working load.

Versatility, strength, and even smart technology make the Hoyer Presence Professional Patient Lift stand out among lift devices. Here are the key features:

- Battery-powered

- Smart Monitor technology

- Intuitive Pushpad for assisting with movement initiation

- Swan Neck style legs to allow the lift to move closer to the patient

- Low Leg Option Kit for fitting under beds and other spots with low clearance

- Easy to use powered base

- 6-point cradle

- Ergonomic foot pad to make initial movement easier

- Hand clip control for holding the pendant in place

This lift is great for larger patients. It’s a dynamic device, capable of several adjustments to make life easier for patients and caregivers. Cutting-edge design features and technology make the Presence an impressive tool that can provide major quality of life improvements for its users.

Hydraulic Patient Lifts

A hydraulic patient lift is operated manually by the use of a hand crank or push lever. After lifting the patient, the operator can move the patient using the lift’s wheels, then lower them down when ready.

Hydraulic lifts are more hands-on than electric lifts, as human power is required during the movement phases of patient transfers. However, the cranks and levers are typically easy to use without great exertion, thanks to the use of hydraulics.

There are two more benefits to choosing a hydraulic lift: they tend to be priced lower than electric lifts, and they do not require electricity, allowing for worry-free operation during a power outage.

If you’re new to patient lifts, it’s perfectly natural to be a bit intimidated by the concept of hydraulic lifts. Fortunately, many people have gone through the same learning process. There’s lots of great info out there to help guide you.

See the video below to get a better idea of what lifting a patient manually with a hydraulic lift looks like:

It’s easier than you’d think to move a person’s weight with a hydraulic lift. That’s because the hydraulic fluid is doing much of the work for you.

Here are three excellent hydraulic patient lifts to consider:

BestLift PL400H Hydraulic

The innovative BestLift PL400H is a great first lift and can be upgraded at any time to an electric lift. Here are the basic specifications for the PL400H:

- Hydraulic system

- 400lb capacity

- Convertible and portable

- 6-point spreader bar

This model is stable, durable, and can be disassembled with ease. It’s a good model for users looking for their first lift as the need for patient transfers enters their lives. When desired, an electric kit can upgrade the model to become an electric lift.

Hoyer Advance Folding Lift

The Hoyer Advance Folding Lift is available in both electric and hydraulic models. With the hydraulic model, the operator uses a hydraulic pump for manual raising and lowering of the lift.

Here are some key product details for the Advance Folding Lift:

- Electric system or hydraulic system

- 340lb capacity

- Lightweight, aluminum material

- Swan Neck style legs to allow the device to move closer to the patient

This lift is foldable and lightweight, so it’s extra portable in comparison to some other lifts. Caretakers can fold it up, roll it out of the house, and place it in the car trunk to take it anywhere.

The Hoyer Advance also features a versatile leg design that allows it to maneuver closely around obstacles, which helps for safe and easy transfers.

Invacare 9805P Hydraulic Lift

The Invacare 9805P Hydraulic Lift has a simple design that’s easy to understand and operate. Here are the basic details for this model:

- Hydraulic system

- 450lb capacity

- Convertible and portable

- 6-point spreader bar

The 9805P allows for 360-degree rotation without side-to-side swaying. Its broad height range allows patients to be lifted from various positions, and its low-friction casters allow for smooth movements.

This lightweight lift is easy to set up, disassemble, and transport.

Making Patient Transfers as Easy as Possible

Operating a patient lift can be scary at first. But, thanks to amazing advances in lift technology, it’s so much easier than it used to be to help dependent patients move around and live their best lives.

Your home is not a hospital, but that doesn’t mean it can’t contain cutting-edge medical technology. Thanks to affordable prices and convenient storage options, the lift device you need is within reach for home use.

Let Dansons Medical connect you to the patient lift and other home medical technologies that you need. View our full patient lift selection today, including electric patient lifts, hydraulic patient lifts, slings, and lift parts.

You’ll get free standard shipping on any product shipped domestically to the mainland United States. Most products will be received within 3-5 business days after they’ve been shipped.

Visit our FAQ to learn more or contact us with any questions.

- Dansons Medical

Bestcare - What System Does My Patient Lift Use? 0

You can understand what system your lift uses by looking at its serial number.

Here's an example of a Serial Number: SA600EL17050100

Please use the following guide to understand your serial number:

| SA | Type of lift. Can start with PL(patient lift) SA(sit-to-stand) and STA(standing-transfer-aid) |

| 600 | Weight capacity (400/500/600 available) |

| EL |

Model (This sequence is not on every serial number. Older units circa 2017 or older may include this but with possible conversions to another unit such as PL400EL->PL400E makes this sequence obsolete. |

| 17 | Production Year |

| 05 | Production Month |

| 01 | Production Plant (0/1/2/9 available) |

| 000 | Batch Number |

TiMotion System

If the customers have a Production plant number of 1 or 2 they WILL have newer TiMotion electronic system and will require those parts.

Performance and Legacy System

We introduced the Performance system in the 3rd quarter of 2013. So, from Sept 2013 to January 2017, we were selling both lifts with Legacy and Performance systems. In 2017, we stopped selling Legacy lifts but do have dealers that stocked their own inventory so it’s possible a customer may order a lift later that same year and have older electronic. There were also many conversions between the two when inventory was low so for older lifts it will be best to makes sure they match up by their control box picture to distinguish between Performance and Legacy System.

For customers that have a Production plant number of 0 and Production year of 2012 or older they will most likely have Legacy electronics.

- Dansons Medical

Lifts

Lifts

Patient Lifts

Patient Lifts

Stand Assists

Stand Assists

Standing Aids

Standing Aids

Ceiling Lifts

Ceiling Lifts

Slings

Slings

Lift Parts

Lift Parts

Wheelchairs

Wheelchairs

Ramps

Ramps

Modular

Modular

Portable

Portable

Ergonomic

Ergonomic

Portable

Portable

Reclining

Reclining

Standing

Standing

Sporting

Sporting

Bariatric

Bariatric

Parts & Accessories

Parts & Accessories

Walking Aids

Walking Aids

Rollator Walkers

Rollator Walkers

Canes

Canes

Parts & Accessories

Parts & Accessories

Pool

Pool

Pool Lifts

Pool Lifts

Pool Fitness and Therapy

Pool Fitness and Therapy

Pool Access Chairs

Pool Access Chairs

Slings

Slings

Parts & Accessories

Parts & Accessories

Beds

Beds

Electric Beds

Electric Beds

Mattresses

Mattresses

Overbed Table

Overbed Table

Oxygen

Oxygen

Concentrators

Concentrators

Parts & Accessories

Parts & Accessories

Bed Accessories

Bed Accessories

Bed Parts

Bed Parts

Chairs

Chairs

Medical Recliners

Medical Recliners

Parts & Accessories

Parts & Accessories

Bath

Bath

Toilet Lifts

Toilet Lifts

Bath Lifts

Bath Lifts

Shower Seats

Shower Seats

Parts & Accessories

Parts & Accessories

Dansons Products

Dansons Products

Physical Therapy

Physical Therapy

Exercise Equipment

Exercise Equipment

Compression

Compression

Hot and Cold Therapy

Hot and Cold Therapy

Stretching and Balance

Stretching and Balance

Parts & Accessories

Parts & Accessories

Transfer Aids

Transfer Aids

Cushions

Cushions